When you’reinstalling a low slope roof on a commercial property, the stakes are high. Certain well-installed systems can last over 30 years, reducing energy costs and preventing leaks throughout that entire lifespan. A poorly installed roof, on the other hand, is a pathway to expensive commercial flat roof repairs and occupant complaints. So, before you commit to a low slope roofing system or contractor, make sure you understand these six essential considerations for roofing a low slope roof the right way.

Quick Answer: What Should You Consider Before Installing a Commercial Roof?

Table of Contents

If you want to install a low slope (or flat) commercial roof, be sure to account for these six key factors:

- Flat Roof Slope: The slope affects drainage, material choice, and warranty eligibility.

- Material Compatibility: Not all roof materials are suitable for low slope roofs. This includes asphalt shingles.

- Roof Assembly Layers: The roof deck and insulation lie below your membrane, which is applied onto the rest of the assembly with an attachment system. All layers must be assembled correctly to avoid costly issues.

- Attachment Method: Choose between mechanically fastened, adhered, or ballasted systems based on your building’s unique needs.

- The Importance of Contractors: Smart buyers need licensed commercial flat roofing contractors who offer warranties and understand the local climate.

- Long-Term Maintenance: Based on the roof’s projected lifespan, plan for upkeep and (some) repairs from the start.

If you understand these, you’ll be better prepared to avoid unnecessary commercial flat roof repairs down the line.

Looking for Low-Slope Roofing Services?

Primer: Low Slope Roofs vs. Flat Roofs

Before we get into the weeds, you should know that the terms “flat roof” and “low slope roof” are essentially synonyms, commonly referring to any roof with a slope ratio lower than 2:12(2 “rise” for every 12 “run,” if you’d prefer to picture it as a high school geometry problem).

Of course, roofers most frequently apply the flat roof designation to especially low pitch roofs; for example, the lowest slope standing seam roof systems currently in widespread use have a slope ratio of ¼:12. Colloquially, however, most contractors call any low slope roof a flat roof, and for that reason, we’ll use the terms interchangeably in this article.

Point 1: The Slope of Your Roof Affects Everything

Even a flat-looking roof has a slight slope for drainage. Most commercial flat roofs have a slope between ¼:12 and 2:12 per foot, though some exceed even this and reach upwards of 3:12(whether this is even still a low slope roof, we’ll leave for you to decide). This low roof slope influences a variety of factors, including:

- Ponding water: A proper slope directs rainwater flow downward and prevents ponding, which can accelerate membrane degradation and promote mold growth.

- Repair and maintenance frequency: Areas with poor slope are more prone to leakage over time due to ponding water.

- Warranty eligibility: Many manufacturers require minimum slope thresholds (¼:12, for example) to issue a full-system warranty.

So, what should you do with this information? Always make sure your contractor evaluates both structural and design slope before recommending a product. Do this by taking time to ask questions before you sign a contract, verifying your contractor’s experience and, consequently, saving yourself money in the long haul.

Point 2: Not All Roofing Materials Work for Low Slopes

Many roofing materials aren’t suited for low pitch applications. For example, asphalt shingles (as well as many other materials you’d put on your home’s roof) often require steeper slopes. Instead, you’ll want to use systems specifically designed for roofing a low slope roof, such as:

- Heat-welded thermoplastics like TPO and PVC(for a comparison between these two varieties, check out this article)

- Other single-ply membranes like EPDM

- Multi-layer systems likebuilt-up roofing (BUR)or modified bitumen roofing

Need help comparing these membrane varieties and deciding which is best for your building? We’ve included a table below covering the basics:

Membrane Type: | Best For: |

TPO | Cost-conscious projects, sunny areas |

PVC | Restaurants, industrial facilities |

EPDM | Colder climates, all-around performance |

BUR | High-traffic commercial rooftops, buyers who prioritize a long lifespan |

Modified Bitumen | High-traffic commercial rooftops, buyers who prioritize affordability |

Point 3: The Roof Is a System, Not a Single Layer

A commercial roof assembly includes much more than just the membrane. In fact, every low slope commercial roofing system typically includes the following:

- Roof deck/substrate: Usually composed of steel, wood, or concrete, this base layer structurally supports the rest of the roof assembly.

- Insulation: A layer (or in buildings with extra protection, two layers) of foam meant to keep heat from entering or leaving your building.

- Attachment system: The fasteners, adhesive, or ballast that bindsthe membrane to the insulation.

- Membrane: The top layer that waterproofs the roof assembly.

Choosing the right commercial flat roof company for your project is crucial, since improper installation of these layers can lead to thermal bridging, blistering, moisture entrapment, and similar issues, leaving you to endure a costly repair process after just a few years.

Point 4: Attachment Methods Can Make or Break Performance

How your low slope roof material is attached affects its longevity and cost. Common methods include:

- Mechanical attachment: Fastening with screws and plates. This system is widely used and cost-effective, but the screws and plates can serve as conduits for thermal bridging.

- Full adhesion: Gluing the membrane directly to the substrate. This is ideal for windy and rainyenvironments but can cost more than mechanical attachment.

- Ballasted attachment: A loose-laid membrane is held down by river rock. This system provides exceptional resistance to wind uplift and thermal bridging, but its weightlends it a higher price tag and makes it unsuitable for older buildings.

- Screw and glue attachment: In particularly high-wind areas with frequent hurricanes (such as coastal North Carolina), this less common hybrid between mechanical attachment and full adhesion may be a good call. However, the use of two different attachment methods significantly raises the project’s price, and because of that, we don’t recommend this system for areas with mild weather.

Choosing the right attachment method is a balancing act between sticking to your budget and accounting for your area’s weather conditions. To make sure you’re getting your money’s worth, consult with a roofing contractor who understands the local climate.

Point 5: Contractor Quality Makes All the Difference

Speaking of contractors, even the best roofing for a low slope roof can fail if improperly installed. Work only with certified commercial flat roofing contractors who:

- Educate customers: Any contractor worth their salt with take the time to explain to you how your roof is being installed. If a prospective contractor isn’t clearly communicating, they may not be a fit for you.

- Offer warranties: In addition to membrane manufacturer warranties, most contractors offer warranties on installation and long-term repairs in case they make any mistakes in the initial construction process. If they fail to do this, take this as a sign that the quality of their work may be subpar.

- Document their work: Reputable contractors take photos of each state of the installation (e.g., insulation layout, seam welding, flashing details, etc.) to verify quality and support warranty claims. Failure to do so reflects a lack of professionalism that may extend to the quality of their work.

Avoid unlicensed crews and contractors who offer only vague proposals. After all, low bids from inexperienced commercial flat roofing companies may cost you more in long-term commercial flat roof repair expenses.

Point 6: Plan for Long-Term Maintenance

Because they’re more vulnerable to water ponding and excessive UV ray exposure, flat roof commercial systems need proactive maintenance, even when installed correctly. Over time, continuous sunlight and foot traffic can cause shrinkage, cracking, and seam failure. To better prepare yourself, ask your contractor about:

- The roof’s expected lifespan

- Recommended inspection frequency

- What’s covered under your warranty, and what isn’t

While the lifespan of the overall roof system varies wildly based on installation quality and local weather conditions, here’s a general estimate of how long each membrane we’ve discussed will last:

Membrane Type | Lifespan |

TPO | 20-30 years |

PVC | 20–30 years |

EPDM | 20–30+ years |

BUR | 20–30 years |

Modified Bitumen | 15–25 years |

Frequently Asked Questions (FAQ)

Poor installation is the root of all evil when it comes to low pitch roofing failure, as it can cause ponding water, leaks, thermal bridging, and similar issues. However, consistent exposure to sunlight and the elements causes wear-and-tear even to well-installed roofs, and frequent inspections are the best way to avoid any issues from causing full roof failure.

A flat slope roofcan often be repaired if damage is isolated, but these repairs must be done using the correct low slope roof materials and following manufacturer standards to avoid voiding warranties. Of course, for any roof system that is aging or has widespread damage, full replacement will likely bemore cost-effective, regardless of the slope in the roof.

A well-installed commercial flat roof typically lasts 20–30 years, depending on climate conditions and maintenance. EPDM roofs tend to last the longest, but most flat roofing systems can reach the 25-year mark if cared for properly.

Yes, often with multiple. While manufacturers of roofing material for low slopes usually offer warranties for issues with the roof itself, most contractors cover poor installation. Always document each step of the installation process to back up any potential warranty claims.

Final Thoughts: Invest Now to Save Later

If installed correctly, a low slope commercial roof acts as a long-term investment in your building’s performance, saving you repair and energy costs while raising rental value. Whatever low slope roof options you choose, making informed decisions now about slope, materials, attachment methods, and installer qualifications can save you thousands in the future.

Are You Looking for a Commercial Flat Roof Contractor?

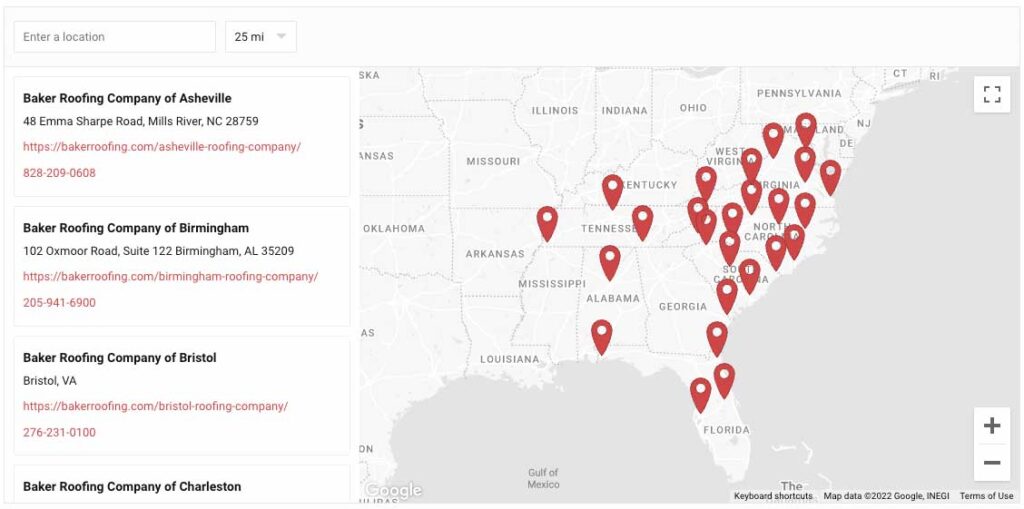

As a company owner or facilities manager, you’re far too busy dealing with your business to worry about your roof. Luckily, Baker Roofing Company specializes in reliable work that stands the test of time, meaning that once you hire us, you won’t have to stress about leaks, rot, or any other roofing issues.

For over 110 years and across the American Southeast, Baker has offered premium commercial roofing services in line with our motto of “Always Good Work.” If you want an issue-free roof that will last you decades, request a free quotebelow. Let’sbuild something that lasts.

More Information on Low Slope Roofing

Flat Roof Skylights: Design, Installation, and Maintenance Guide

Adding a skylight to a commercial flat roof can completely transform the atmosphere of your…

Roof Coping: Everything You Need to Know

If your property has a flat roof (or even certain forms of sloped roof), a…

TPO vs. PVC: Which Is Best for Your Business’ Roof?

In the fun, high-action world of single ply membrane roofing, two products dominate the market:…