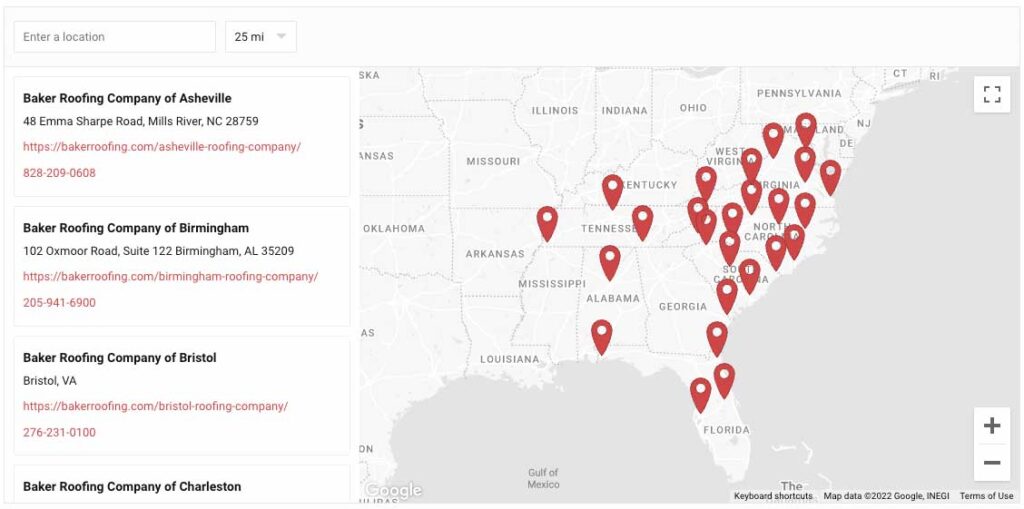

With 26 offices across the Southeastern United States, it can sometimes be a challenge to get to know all of our employees. This month, however, we jumped at the chance to catch up with, and get to know one of our wonderful Operations Directors, Zach, in our Charleston branch.

Zach came to Baker in 2013, after working independently in roofing for a number of years. Prior to joining the Baker family, he spent his time running his own roofing company, going to school, learning the ins and outs of roofing, and raising a family in Montana. The long, cold winters of Montana eventually got old, so Zach, his wife, and three children started looking at places with warmer weather, ultimately landing with Baker Roofing Company in Raleigh, North Carolina.

In 2013 Zach began work at the Raleigh office. As a project manager, those who worked with him described him as professional, thorough, and able to exceed customer expectations at every turn. Challenges, such as limiting noise and on-site activity, did not limit or intimidate Zach. He continued to grow within the company, learning as much as he could, and taking part in Baker’s Leadership Program in the fall of 2016.

Throughout the six months of the Leadership Program, Zach worked with his cohort on projects and assignments that took them out of their comfort zone and challenged him to interact differently with the people he worked with. In his cohort, Zach worked closely with and got to know Matt, who is now the General Manager of Baker Roofing of Charleston. When asked about working with Zach throughout the leadership course, Matt told us, “I was impressed with Zach’s core values and his ability to translate those into everything that he does.”

In the Spring of 2017, Zach was offered the opportunity to take on the Operations Manager role in the Charleston office. He now spends his days being the first person at the office to get a jumpstart on the day and completes his office work before his coworkers come in. Zach helps his crews set up and get ready for their workday, attends meetings, or spends the majority of his day managing his crews. He is happy to go beyond his traditional duties, sometimes even escaping the Operations segment to help a coworker or crewmember with a technological or phone issue. On working with Zach in an Operations capacity, his (now manager) Matt told us, “Operationally, Zach has the enormous capacity – he makes the daily challenges associated with construction look effortless, and identifies, plans for, and solves problems with a positive attitude. People naturally want to work with Zach – he is a leader, a mentor, and a respected professional.”

On behalf of Baker Roofing Company, we would like to say thank you to Zach for all of his hard work and dedication. We are proud to have members of the Baker team that lives up to our standards of Always Good Work and consider employees like Zach a family member and friend.