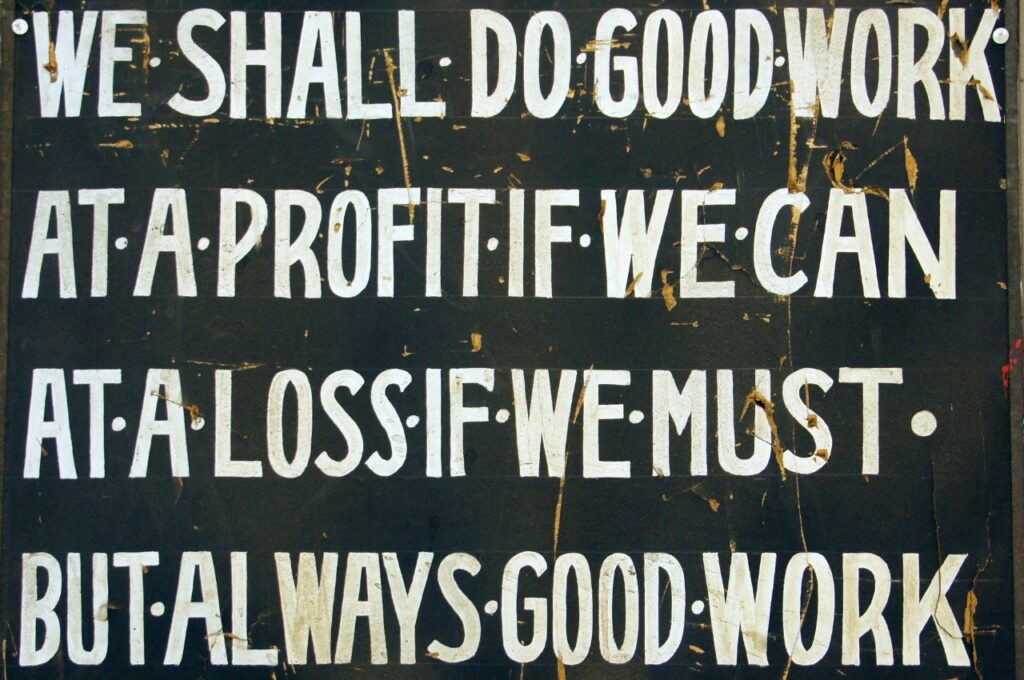

We shall do good work | At a profit if we can | At a loss if we must | But Always Good Work

With over 100 years of experience, Baker Roofing Company has grown to become one of the nation’s largest roofing contractors.

In 1915 WP Baker hung a sign in his downtown Raleigh shop indicating that Baker Roofing (then Baker Rawls Tin Shop) was open for business. That sign read ‘We shall do good work. At a profit, if we can, at a loss if we must, but always good work.” Today, that sign can be found hanging in the lobby of our Raleigh headquarters (Pictured to the right with Prentiss (L) and Frank (R)) to act as a daily reminder of the values that drive all of team Baker.

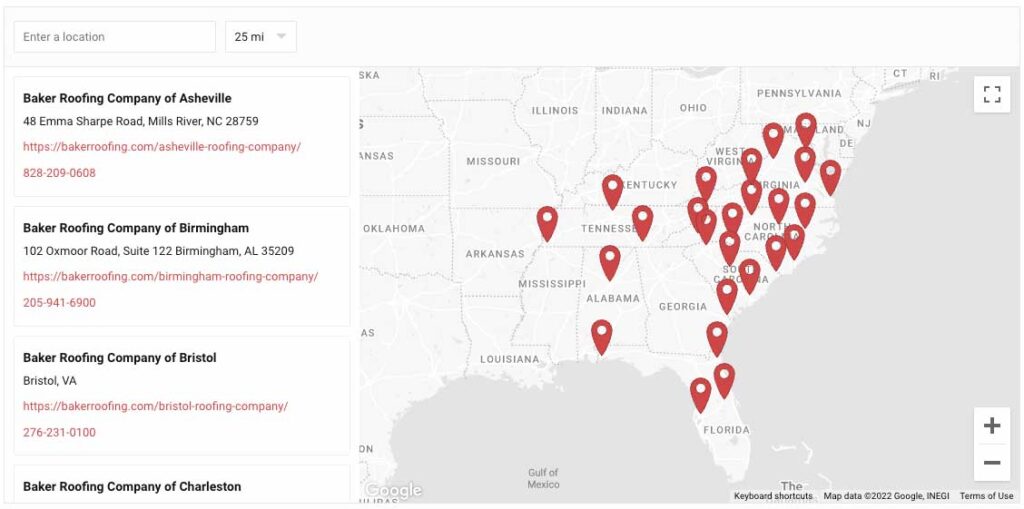

Since that day in 1915, Baker Roofing has grown to become one of the nation’s largest and most respected roofing contractors. Baker Roofing Company now has over 20 locations across the Southeast and performs work all across the US.

To survive in business for over 100 years is no simple feat. Almost certainly, this success can be attributed to values-based family ownership and a century-old mission to do Always Good Work. We sat down with our humble leaders and third-generation Baker men, Prentiss and Frank Baker to share belly laughs over old times and get to know their hearts for serving others. Read our blog for the full interview!

William Prentiss Baker rode a mule from Harnett County to Raleigh, North Carolina, in January 1901. Born July 27, 1886, he was a 14-year-old boy running from a hard father and a hardscrabble farm life and riding to a bustling capital city that offered opportunity and promise.

It was a new day, a new year, a new century, and for the young Baker, a new life. In 1902, Prentiss began learning the trade of a tinsmith for which he was paid 50 cents a week. The southwest quadrant of downtown Raleigh was home to roofing and sheet metal shops, small manufacturing companies, warehouse, and rooming and boarding houses. It was in this part of the growing city that Baker opened his own business on September 20, 1915. Like its owner, the name was straightforward: “W.P. Baker Co., tinner.”

Located on 419 Gale St., four blocks south of the Capitol, the company first appeared in the 1917 City Directory and at that time Prentiss posted a small sign on the front door that was in all capital letters, stating “We shall do good work, at a profit if we can at a loss if we must, but always good work.” A sincere promise that remains part of Baker’s culture and drives all of Baker Roofing Company.

Since that day, Baker Roofing Company has grown to become the 2nd largest contractor in the nation with over 20 offices across the southeast.

Alex Manring

Alex Manring is Director of Brand Marketing at Baker Roofing Company, where she has been part of the marketing team for 10 years. In her role, she oversees brand strategy and marketing initiatives that drive the company's growth across the Eastern United States. When she's not working, Alex enjoys reading, perfecting her sourdough bread, exploring new coffee shops and restaurants, and traveling with her husband, Cole, their twin daughters, Hadley and Coven, and their doodle, Nuke.