In the fun, high-action world of single ply membrane roofing, two products dominate the market: TPO and PVC. Of course, unless you’re a grizzled veteran of facility management, you’ve likely never heard of most types of roofing membranes to begin with, leaving you to wonder what difference membrane types even makes.

However, if your business currently has a low-slope or flat roof, these crucial commercial roofing materials are likely keeping you from getting soaked by rainwater infiltration or scorched by the sun’s heat. So, in this article, we’ll cover the importance of TPO and PVC membranes, the similarities and differences between them, and how to decide which is better for your business.

Table of Contents

Quick Answer: TPO vs. PVC

TPO is generally more affordable and highly UV resistant, making it ideal for offices, warehouses, and retail spaces in sunny climates. PVC offers superior chemical and fire resistance, making it the go-to choice for restaurants, factories, and industrial facilities.

What Are TPO and PVC Membranes?

Looking for Single-Ply Commercial Flat Roofing Services?

To review, roofing membranes are a layer of your roof that covers the roof deck and insulation, protecting the parts of your roofing system that do the (literal) heavy lifting. Under this broader umbrella, TPO and PVC are both types of heat-welded thermoplastic roofing membranes, a variety of single ply membrane used on low-slope and flat roofs that’s sealed at the seams using hot air.

Heat-welded thermoplastics create reliably waterproof and monolithic roofs that also reflect sunlight, keeping your business’ interior cool and reducing AC costs. Depending on their quality, thermoplastics may even includeflame retarders, UV light inhibitors, and agents that protect against mold and bacteria (this is especially true of TPO, but such add-ons are also common with PVC). You can find the two major types of thermoplastic membranes below:

- TPO, which stands for thermoplastic polyolefin roofing membrane, is a cost-effective thermoplastic membrane known for being flexible in colder environments and offering unparalleled resistance to UV radiation. Despite a common misconception that causes all sorts of roof-related confusion, not all thermoplastics are TPO, and there are several varieties that exist even beyond TPO and PVC.

- PVC, also known as polyvinyl chloride, is a higher-end type of thermoplastic that sports impressive chemical and fire resistance. For this reason, they’re usually used to roof restaurants, factories, and other buildings where those materials are frequently used.

Benefits of TPO Roofing vs. PVC Roofing

As you might have inferred from the previous section, both TPO and PVC have specific use cases, and which is best for you depends entirely on what type of business you run and what types of protection you prioritize. To help with your decision, here are some factors you may want to consider:

- Affordability: Because of less investment in fire and chemical resistance, TPO tends to be the more affordable option. However, if you run a business that could benefit from such resistance, avoiding future maintenance may justify the upfront cost.

- Durability: TPO and PVC largely have the same lifespan, surviving around 20-30years if well-maintained. However, as we’ve already covered, in environments where grease, oil, and fire are present, TPO membranes will deteriorate faster, making PVC the slightly more resilient option.

- Energy Efficiency: TPO tends to be more UV resistant due to having fewer UV-vulnerable plasticizers and using more UV inhibitors, reducing your cooling costs and improving your energy efficiency. However, both membranes sport above-average reflectivity compared to the median flat roof, and the disparity between them is modest.

- Installation: PVC membranes have been around twice as long as their TPO counterparts, meaning their installation process has been better refined over time. As such, you or your roofing contractor may face less hassle installing PVC than you would otherwise experience with TPO.

So, which membrane is right for your business? See the table below to help you decide:

Business Type | TPO vs. PVC Roofing |

Office Buildings | TPO |

Warehouses | TPO |

Restaurants | PVC |

Manufacturing Plants | PVC |

Retail Stores | TPO or PVC |

Frequently Asked Questions (FAQs)

TPO is more affordable and UV resistant, while PVC offers superior chemical and fire resistance.

Both can last 20–30 years with proper installation and maintenance.

TPO excels in sunny, hot climates thanks to its superior UV resistance, while PVC is better in chemical-heavy or industrial areas regardless of climate.

Both require routine inspections, cleaning debris from the surface and drainage areas, and timely repair of punctures to maintain performance.

Yes, in many cases they can be installed over an existing roof if the deck is in good condition. However, depending on your locality, building codes and weight limit laws may interfere with this, meaning you should check with a contractor to make sure you’re good to go.

Final Thoughts

In the end, every property is different, meaning that the best way to decide which roofing membrane to use is to seek help from a qualified roofing contractor. A professional can assess your building’s structure, climate zone, and long-term needs to recommend the most cost-effective and durable option.

Are You Looking for a Commercial Roof Membrane Contractor?

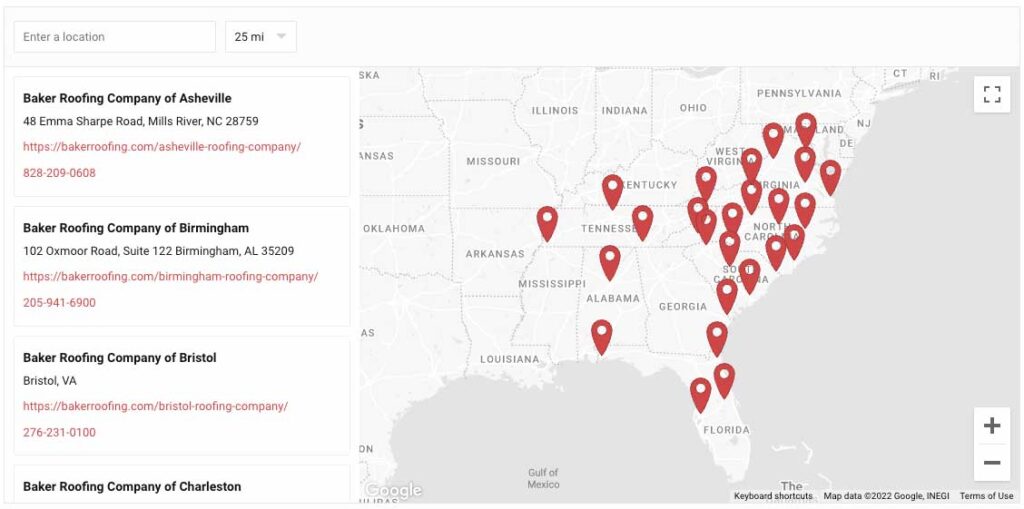

At Baker Roofing Company, we specialize in TPO and PVC installation across the American Southeast. For 110 years, we’ve offered high-quality commercial roofing craftsmanship, at a profit if we can and a loss if we must. Request a free quote below!