From reading flight maps to warranty specs, Alex has had one of the most shocking career shifts we've heard at Baker Roofing! Learn more about our own "Maverick" and his journey from being a pilot to roofing below.

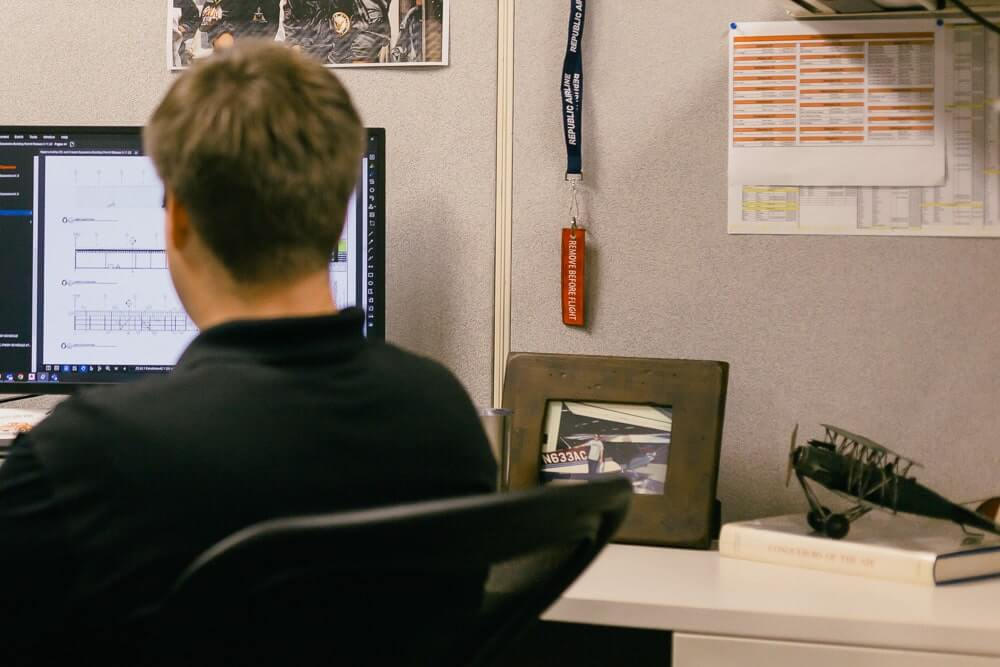

Meet Alex Hephner, a participant in our Construction Management Program currently completing Phase 2 of his training: pre-construction and submittals! For National Roofing Week, we asked Alex to share about his experience making the transition from aviation to roofing.