You rarely see a commercial flat roof without a metal deck lurking underneath. That ribbed steel bears the weight of the roof and fights wind and snow, which ensures your building stays dry through decades of inclement weather and normal wear alike.

If you’re considering flat roof installation or replacement, understanding the decking that sits below gives you control over a project that could otherwise lack transparency. And luckily for you, Baker Roofing has over 100 years of experience installing and repairing metal roof decks on commercial buildings across the Southeast, which makes us the perfect source for you to reference.

To that end, this article walks you through what metal roof decking is, how it works, and how to choose the right deck for your needs, no engineering degree required.

Table of Contents

Quick Answer

Metal roof decking refers to corrugated (i.e., ribbed) steel panels installed as the structural base beneath a commercial roof system. Once the decking is in place, contractors add insulation and a weatherproof roof membrane (like TPO, EPDM, or built-up roofing) on top. It’s most commonly used with flat roofs, though it can also work with some sloped systems.

Looking for Metal Roof Decking Services?

The Context: What Is a Roof Deck?

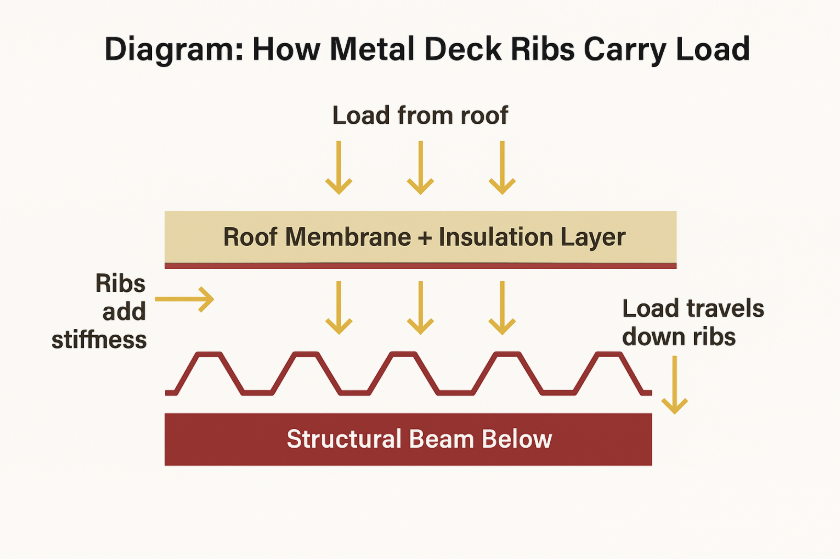

Roof decking is part of the broader flat roof assembly, which consists of a deck, insulation, and a membrane. The deck is the lowest layer, and its purpose is to support the structure of the rest of the assembly.

A deck acts as the foundation for everything above it, and without a deck rated for the right load and span, your roof is like a skyscraper built on sand. Because of that, metal is one very common material used for decking.

What Is Metal Roof Decking?

Metal decking is the ribbed, or corrugated, steel platform that gives a commercial roof its strength and spanning ability. Instead of acting as the waterproofing layer, it works behind the scenes: the deck ties the building’s structural frame together and carries the weight of everything on top of the roof, whether it be equipment, foot traffic, snow, wind uplift, and more.

What makes metal decking valuable is not just its material but its geometry. The corrugated metal deck ribs act like rows of miniature beams, letting the deck support long distances between joists without sagging.

Metal roof decking is primarily used on low slope roofs because these assemblies need a rigid, load-bearing platform to support insulation, waterproof membranes, rooftop equipment, and sometimes even foot traffic. Conversely, steep slope roofs shed water through gravity and typically only require a simple nailable surface like plywood, not structural steel.

Metal decking’s combination of high strength and low weight is why it has become the backbone of modern low-slope construction. It’s fast to install while still being durable enough to outlive multiple membrane replacements.

Why Metal Roof Decking Matters

There are several reasons why metal decking stands out compared to other decking materials, like wood and concrete. Consider the following:

- Strength-to-weight efficiency: As a cold-rolled steel system (usually 22–16 gauge), metal decking delivers a higher load capacity than materials like wood without adding excessive dead weight. That keeps structural framing lighter and, as a consequence, more cost-effective than other heavy-duty options like concrete.

- Durability against weather and wear: Properly galvanized (or coated) metal decks resist corrosion and wind for decades. Plus, they handle snow, heavy rain, and rooftop equipment with considerably less maintenance than plywood decking.

- Flexibility for various roofing systems: Metal decking works under built-up roofs, single-ply membranes (TPO, PVC, or EPDM), modified bitumen, and virtually any other low-slope commercial roof system. That makes it ideal for a wide range of commercial purposes, such as warehouses, retail spaces, schools, offices, and restaurants.

All of this adds up to a decking system that’s strong and adaptable, built to support commercial roofs for the long haul.

Types of Metal Decking

Most commercial roofs in the U.S. use some variation of corrugated metal deck, but not all deck profiles behave the same. The shape and depth of the ribs determine how far the deck can span and how much load it can carry. Here’s a practical way to think about the options.

B-Deck: The Everyday Workhorse

If you’ve ever been inside a big-box store or an office building built after 1970, there’s a good chance B-deck is holding the roof up. It’s the “standard” metal deck profile for a reason.

People choose it because:

- It’s shallow (1.5 inches deep), which makes it easy to work with and compatible with almost any low-slope roofing system.

- It comes in wide sheets (usually 36 inches), so installers can lay a lot of square footage quickly, reducing the installation costs you have to pay.

- It handles short and medium spans well, which is ideal for typical commercial framing where beams or joists aren’t spaced extremely far apart.

B-deck shines most in:

- Retail buildings

- Offices and schools

- Restaurants

- Medical clinics

- Small warehouses

Think of B-deck as your dependable all-purpose deck; it’s strong enough for most jobs and cost-effective, which is why it’s widely used.

N-Deck: The Long-Span Specialist

N-deck is the deeper, heavier-duty cousin of B-deck. At 3 inches deep, it has taller ribs that give it a more pronounced profile. That extra depth lets it do something B-deck can’t: span long distances without sagging or needing extra structural support.

People choose it because:

- It can bridge wide gaps between beams, which reduces the amount of steel framing needed in the building.

- It’s ideal when owners want a large, open interior without a lot of columns (think wide-open warehouse aisles or manufacturing floors),

- It handles heavy rooftop loads (HVAC equipment, rooftop traffic, etc.) exceptionally well, especially in thicker gauges.

N-deck shines most in:

- Distribution centers

- Large industrial facilities

- Big warehouse retailers

- Aircraft hangars

- Large event spaces

If B-deck is a sedan, N-deck is a pickup truck. It’s not for everybody, but it’s perfect for heavy-duty applications that demand high strength that can span long distances (even if this demands a higher installation cost).

Other Deck Types

Most roofing projects stick to B- or N-deck, but certain buildings need specialty profiles.

- Composite Deck: A type of steel deck that’s designed to work together with a poured concrete slab. The steel sheet isn’t acting alone; once concrete hardens around the deck’s embossed ribs, the two materials lock together and behave as a single structural unit. This system is most common in multi-story buildings, parking decks, and other structures where the roof doubles as an occupied floor.

- Form Deck: A temporary or semi-permanent deck that supports concrete during construction. It’s not a true “roof deck” unless used with additional systems. This system is often integrated with composite decks during the latter’s construction.

- Acoustical Deck: Designed with a perforated underside filled with sound-absorbing insulation. You’ll find it in schools, auditoriums, gymnasiums, labs, or anywhere noise control matters.

These specialty decks don’t appear as often, but when they do, it’s because the building has specific structural or acoustic requirements.

Gauges and Finishes: How Metal Decking Gets Its Strength

Of course, the metal deck steel thickness and protective coating are just as important as rib shape. They determine how strong the deck is and how well it resists corrosion over time.

Gauges: The Real Measure of Strength

Steel gauge is basically the thickness of the panel. The lower the number, the thicker (and because of that, stronger) the steel.

Common gauges for a metal roof deck include:

- 22 gauge: Lighter, more flexible, good for short spans

- 20 gauge: Middle-of-the-road strength, works in most commercial settings

- 18 gauge: Significantly stronger, used for heavier loads

- 16 gauge: Heavy-duty and used where spans are long or equipment loads are high

A good rule of thumb: the thinner the gauge, the lower the price but shorter the lifespan.

Finishes: Protecting the Steel From the Elements

Although hidden under insulation and a membrane, metal decking still needs proper corrosion protection, especially in climates with high humidity or wide temperature swings.

Because of that, metal decking is typically factory-coated to protect against corrosion, especially since moisture and condensation sometimes occur below the roof membrane.

Most common finishes include:

- G-60 galvanization: A standard zinc coating suitable for normal interior environments.

- G-90 galvanization: A heavier-duty zinc coating used in coastal or humid settings.

- Primer-coated steel: Used as a base layer for additional fireproofing or paint, especially when the deck doesn’t face significant moisture or corrosion risks.

Note that the 60 and 90 figures above refer to the amount of zinc in the coating. G-60 galvanization, for instance, has 0.60 ounces of zinc per square foot, while G-90 has 0.90 oz/square foot.

Choosing the right gauge and finish up front goes a long way toward keeping the deck healthy over its entire service life.

What Does Metal Roof Decking Cost?

Based on recent industry data, typical price ranges for metal roof decking run roughly $3.00 to $7.00 per square foot of raw material. With lower gauges (i.e., thicker metal) and deeper ribs, expect higher cost but proportionally increased load capacity and span strength.

When you add installation labor, you should expect higher project-level roof costs. With that in mind, metal roof decks usually cost $6.00-$13.00 per square foot installed. This puts metal squarely in the mid-price tier for roof deck materials, with it being cheaper than concrete but more expensive than wood.

Of course, prices vary by steel gauge, finish, design loads, and regional labor conditions, so your exact project cost may fall outside these ranges. Still, metal decking stands out as a cost-efficient choice for buildings that need stronger support without the premium price of heavier materials like concrete.

How to Choose the Right Metal Roof Deck: Decision Guide

Picking the right deck profile requires matching the deck to the building’s needs. A few practical questions can point you in the right direction:

- What kind of building do you have? A warehouse, retail store, school, or industrial facility will each place different demands on the roof. Bigger, more open spaces usually mean longer spans and heavier-duty decking.

- How far apart are the supports? If beams or joists are close together, standard B-deck usually fits the bill. Wider spacing, however, often pushes you toward a deeper profile like N-deck.

- What will the roof need to carry? Consider rooftop HVAC units, walkways, snow load, solar arrays, or anything else that adds weight. A greater load usually requires thicker steel.

- What’s the right balance between cost and performance? Lighter gauges cost less, but heavier gauges deliver more strength and stability. Your deck doesn’t have to be overbuilt, but it should be strong enough for the long haul given your property’s unique needs.

- What environment will it live in? If your building sits near the coast or in a humid climate, choose a heavier galvanization like G-90 and consider a thicker gauge to fight corrosion. In milder environments, G-60 and lighter gauges typically perform well, as long as fire-rating requirements are met.

- Are you planning upgrades later? If you might add solar or new HVAC in the future, it’s worth selecting a heavier-duty deck that can handle those changes without major structural work.

Taking these factors into account upfront makes it much easier to choose a deck that will support future upgrades and give the roof system the performance it needs. After all, a little planning often prevents a lot of headaches later.

How to Install Metal Roof Decking (and What to Watch For)

Installation matters as much as design. Of course, we can’t recommend you install decking on your own, given that the work is highly technical, and mistakes could cause leaks and compromised structural performance.

However, we can give you a simplified approach based on standards in the trade. That way, you can ensure that your contractor is following industry best practices and giving you the best service possible. Here’s the step-by-step guide:

- Check the structural supports: Ensure beams or joists are properly spaced, level, and free of debris (the last one is most important, because it’s something you can easily control). Misaligned framing will cause misaligned panels.

- Lay out the first deck panel: Position the panel perpendicular to the supports and square it to the building. The first sheet sets the alignment for the entire roof.

- Fasten the panel to the structure: Use welded or mechanically fastened connections according to the engineer’s specifications (if you don’t follow these, you may void your warranty).

- Install side-lap connections: Side laps are the seams where adjacent deck roofing panels overlap. Button-punch, screw, or weld these so the ribs act together as a unit. This prevents flutter and improves diaphragm strength (i.e., how well your deck can distribute force from wind and seismic activity laterally to the building’s structure).

- Continue setting panels across the roof: Continue installing panels, staggering the end joints (i.e., not aligning the ends of the panels to create a single line) and keeping each sheet tight against the next. Staggering keeps you from having one massive weak line across the roof and helps the deck act as one solid, stable surface.

- Install edge closures and perimeter details: Fill gaps at joints and penetrations (like chimneys) with approved closures to prevent wind uplift or membrane sagging later.

- Inspect the deck before insulation goes on: Check for loose fasteners, misaligned ribs, sharp edges, or damaged panels. Repairs are far easier at this stage.

More Tips for Metal Roof Decking Installation

Beyond that, here are some extra tips to help you ensure your contractor is doing the job correctly:

- Panels should lie flat with no rocking or rattling. Loose deck is a sign of poor fastening or misaligned supports.

- Side laps should feel tight and connected. If you can easily flex the side joint with your hand, the lap isn’t secured properly.

- All perimeter and edge areas should be properly closed. Missing closures allow air infiltration, which leads to condensation and early corrosion. These are two of the most common long-term points of failure.

- Welds and fasteners should be clean and uniform. Proper attachment is what keeps the deck secured to the building, so welds should be consistent and fully fused, and screws should land squarely on the structural supports.

- The contractor should perform a full walk-through before insulation begins.

This is your chance to catch small issues before they turn into major ones hidden beneath the roof system.

A well-fastened deck sets the tone for the whole roofing project. If the installation is solid from the start, everything that goes on top of it has a much better chance of lasting.

Pros and Cons of Metal Roof Decking

Metal roof decking comes with a long list of strengths, but it isn’t perfect for every situation. Here are some major pros and cons.

Pros

- Strong structural support, even under heavy loads and equipment (this is especially true of N-deck).

- Durable and long-lasting, especially when galvanized or properly coated.

- Versatile, allowing it to work well with many types of roof membranes and insulation systems.

- Relatively quick installation compared to wood or concrete decks.

- Lightweight (compared to concrete), which places less demand on building structure and reduces costs.

Cons

- Thermal bridging and condensation risk: especially if insulation is not handled properly.

- Environmental exposure: in coastal or high-humidity zones, you have to address corrosion with appropriate coatings or maintenance.

- Noise: metal can transmit sound or vibration, so it’s not ideal for exposed ceilings unless acoustic measures are taken.

- Mid-tier cost: heavier gauge decking costs more, and fluctuating steel prices impact budget. This means that metal can be more expensive than wood decking (though it’s still cheaper than concrete).

Frequently Asked Questions (FAQs)

That depends on your span and expected loads. For short spans under 10–11 ft., a lighter gauge (22 or 20) B-deck may suffice. For 12-ft.+ spans or heavy rooftop equipment, however, you should consider a heavier gauge (18 or 16) or even N-deck.

Common metal deck profiles include B-deck, the standard 1.5” option, and N-deck, the heavier-duty 3” product suited for spanning longer distances. Other varieties include composite decks, form decks, and acoustical decks specialized for noise reduction, although those are less common in most simple roof applications.

You lay deck roofing panels perpendicular to structural supports, then fasten them with welds or mechanical fasteners according to engineer specs, and finally place insulation and roofing membrane on top. Proper fastening and alignment are the most important ways you can prevent leaks and early structural failure.

A well-installed, properly coated metal deck can easily last 40-70 years, which is often longer than the roof membrane itself. Of course, corrosion resistance and environmental conditions (humidity, salty coastal air, etc.) influence this lifespan.

Final Thoughts

Metal roof decking may not be the most glamorous part of a roof; after all, you don’t even see it once the membrane goes on. Still, it’s the backbone that makes modern commercial roofing possible. It delivers structural support that materials like wood struggle to match, at a lower price point than heavy-duty varieties like concrete.

So, if you’re installing or replacing a commercial low slope roof, choosing the right metal deck profile and gauge (and installing it with care) is one of the best investments you can make up front in your property.

Baker Roofing: Over 110 Years of Experience with Metal and Roofing

Need a certified commercial roofing team that understands metal decking from the ground up? Reach out to BRC for a full roof assessment or project estimate.

We started as a sheet metal shop in 1915, and since then we’ve installed millions of square feet of metal decking systems across commercial facilities in the Southeast.

We handle everything: deck selection, installation, insulation, and membrane application. With Baker, you can rest assured your metal decking will last for decades to come. So, if you’re ready to take the first step toward property-related peace of mind, click the button below to get a free estimate for your roof decking project.